THROWBACK TO 2008

When we originally established Street and Track grade urethane (5 years ago), very few cars were able to achieve over 275 WHP. Now, with upgraded CDFP internals (cam driven fuel pump) and tuning, over 275 WHP is fairly easy to obtain. While there are other variables (driving characteristics, condition of other mounts, etc), engine output is a primary consideration when choosing urethane for your vehicle.

The good news -- We are always improving our product line, so our urethane must evolve with this additional power. The result is a new and improved approach to our urethane applications. Per mount, we are adding additional urethane options for more detailed urethane levels based off of wheel horsepower. These additional urethane options allow for the end user to get the ideal urethane for their power output.

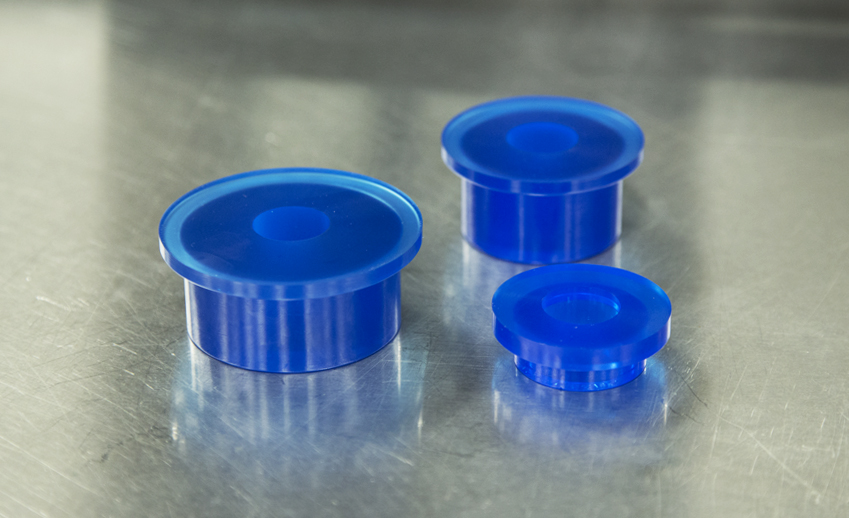

We are releasing three additional urethane options for the R3, S3, R6, and S6 mounts for 2013/2014 - here is the initial launch:

R3 -- Urethane Options

Class 1 - Factory to 275 WHP (Street) -- (New Formula Now Shipping)

Class 2 - 275 to 400 WHP (Aggressive) -- (New Formula Now Shipping)

Class 3 - 400+ WHP (Track) -- (New Formula Now Shipping)

S3 -- Urethane Options

Class 1 - Factory to 275 WHP (Street) -- (New Formula Now Shipping)

Class 2 - 275 to 400 WHP (Aggressive) -- (New Formula Now Shipping)

Class 3 - 400+ WHP (Track) -- (New Formula Now Shipping)

R6 -- Urethane Options

Class 1 - Factory to 275 WHP (Street) -- (New Formula Now Shipping)

Class 2 - 275 to 400 WHP (Aggressive) -- (New Formula Now Shipping)

Class 3 - 400+ WHP (Track) -- (New Formula Now Shipping)

S6 -- Urethane Options

Class 1 - Factory to 275 WHP (Street) -- (New Formula Now Shipping)

Class 2 - 275 to 400 WHP (Aggressive) -- (New Formula Now Shipping)

Class 3 - 400+ WHP (Track) -- (New Formula Now Shipping)

Urethane Updates:

Class 1, Class 2, & Class 3 Polyurethane -- As of June 23, 2014, all engine and differential mounts are now shipping with the new and improved Class 1, 2, or 3 urethane.

S3/S6 Passenger Side -- Street Urethane formula is new and improved as of May 2013. Hardness was increased for a longer lifespan, minimal NVH change.

Our urethane is a wear component - however, we cover it under our lifetime warranty. Thank you for reading, more details to come!

Article by Cullen